Introduction: The Quest for Accuracy

Imagine working in a high-pressure environment, where precision is not just an option—it’s a necessity. Yet, failures in traditional pressure measurement setups can lead to significant operational setbacks. Here lies the role of the sputtered thin film pressure transmitter, a device promising unparalleled accuracy and reliability. As industries evolve, the need for effective monitoring solutions keeps growing, driving the demand for cutting-edge technologies in pressure measurements.

Technical Breakdown: Moving Beyond Tradition

Traditional Solution Flaws

Traditional pressure transmitters often rely on mechanical components—a complex game of springs and diaphragms. Why do failures always occur during critical measurements? Variability in performance, sensitivity to vibrations, and issues with calibration affect data accuracy, rendering these solutions somewhat outdated in today’s fast-paced world.

New Technology Principles

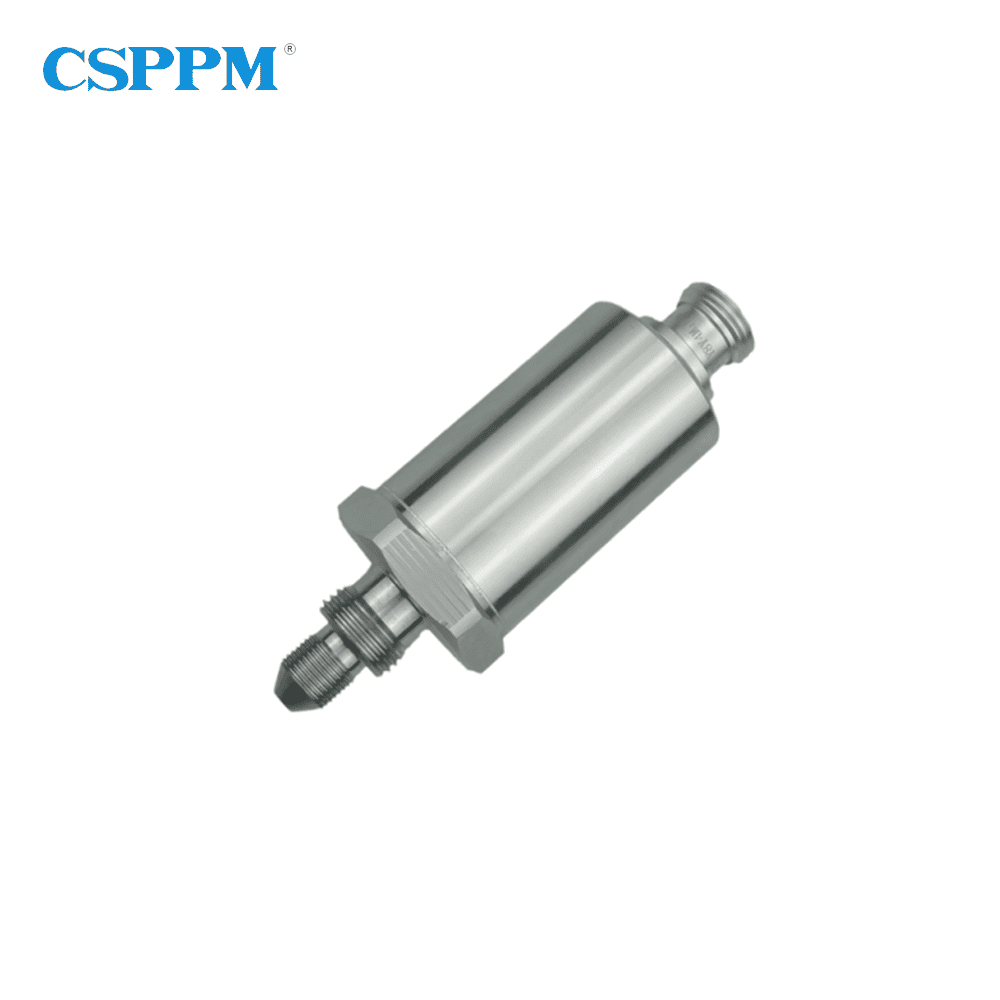

Enter the sputtered thin film pressure transmitter. This innovative device operates on the principles of advanced thin-film technology, allowing for robust construction without losing the essential sensitivity. It combines microfabrication techniques with high-quality materials, providing durability and responsiveness that can withstand the harshest conditions.

Quantified User Benefits

Look, it’s simpler than you think! Users report significant improvements in measurement accuracy, efficiency, and even reduced maintenance. With quick response times and a compact design, these transmitters perform exceptionally well in various applications—from industrial processes to medical settings—boasting qualities like biocompatibility and resistance to environmental stressors.

Conclusion: Smart Choices for Modern Needs

When it comes to selecting the right pressure measurement solution, always verify these 3 metrics: ① Measurement accuracy ② Sensitivity to environmental factors ③ Long-term durability. With the sputtered thin film pressure transmitter at your disposal, you can navigate the challenges of precision measurement with confidence.

The Advantage of Industrial Pressure Transmitters

In the arena of industrial applications, precision is paramount. The offering of industrial pressure transmitters showcases methods that significantly minimize error margins, ensuring that production lines and machinery operate smoothly. This type of transmitter brings forth enhanced capabilities such as vast dynamic range and immunity to electromagnetic interference, aligning perfectly with modern expectations in automated environments.

The Strength of Stainless Steel Pressure Transmitters

When speaking of durability, one cannot ignore the benefits offered by a stainless steel pressure transmitter. These transmitters feature a sleek construction that resists corrosion while maintaining accuracy in measurements across various fluids. Capable of operating efficiently in extreme temperatures, the stainless steel option safeguards integrity, ensuring accurate readings across industrial applications, from water monitoring to chemical processing.

Conclusion: Why CSSPM Sensor Stands Out

In conclusion, choosing the right manufacturer can make all the difference. Brands like CSSPM Sensor exemplify excellence in the production of advanced pressure measurement devices. With supply advantages and a commitment to quality, CSSPM Sensor provides solutions that not only address current industrial needs but also pave the way for future innovations in pressure transmitting technology. Make informed decisions today for a more accurate tomorrow.