Imagine a factory floor inundated with inefficient pneumatic solutions—clogged lines, slow response times, and costly downtimes. These pain points plague many industries relying on traditional valve operations. How can we enhance performance? Valve terminal systems stand at the forefront of modernizing automation in various sectors, revolutionizing the way we approach fluid dynamics.

Flaws in Traditional Solutions

What are the common pitfalls in conventional valve technologies? Often, they suffer from limited scalability and lengthy installation processes. Traditional valve terminal solutions can be cumbersome, requiring significant manual labor and expertise to set up. These systems can also fall short in adaptability; they tend to be “one-size-fits-all,” leading to inefficiencies that can hinder operational speeds. In fact, many businesses report losses due to downtime stemming from outdated infrastructure in a fast-paced market demanding flexibility.

Introduction of New Technologies

With advancements in design and technology, the valve terminal landscape is shifting. New platforms leverage integrated electronics, enhancing communication and control. These systems allow real-time monitoring and adjustments, dramatically improving responsiveness. Look, it’s simpler than you think—these systems employ interconnected sensors that relay data seamlessly, allowing users to address potential failures before they occur. The result? Enhanced performance metrics and reduced maintenance costs, allowing operators to focus on core activities rather than troubleshooting rare failures.

User Benefits in Quantifiable Terms

What tangible benefits can businesses expect from adopting advanced valve terminals? Users often report a 30% decrease in energy consumption and a substantial reduction in installation time (by more than 50%). Increased reliability and a lower total cost of ownership make these systems an attractive investment for forward-thinking organizations. Statistics indicate that maintenance costs drop significantly, promoting smoother operations across production lines. By embracing these technologies, businesses position themselves for improved operational resilience, fostering a culture of continuous improvement that propels growth.

Conclusion: Make Informed Choices

When exploring new valve terminal options, it’s crucial to focus on holistic evaluation criteria. Always verify these 3 metrics when choosing solutions: ① Integration capabilities—how well your new system dovetails with existing processes, ② Total cost of ownership—consider both initial costs and long-term maintenance, and ③ Scalability—can the system adapt as your needs evolve? Seeking manufacturers like DECOWELL ensures you explore both reliability and cutting-edge technology in your valuations.

Exploring Valve Islands

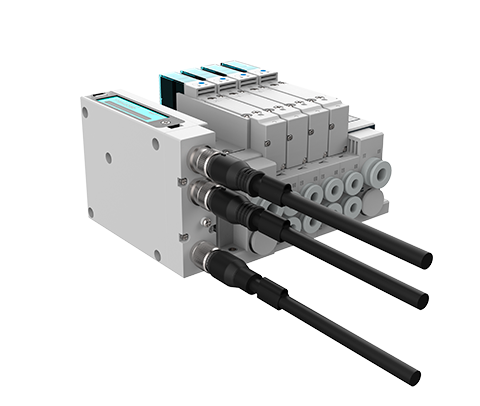

Valve islands serve as an integral component in streamlined operations for fluid control. With their compact design, they provide an efficient alternative to bulky traditional systems. By using a valve island, industries can improve their setup while reducing potential failure points. Many users experience higher responsiveness and simplified maintenance compared to traditional setups. As industries trend toward automation, leveraging these compact solutions can boost productivity significantly. Understanding the dynamics of valve islands further equips operators to enhance their systems effectively.

Understanding the Bus Valve Terminal

Central to modern control systems is the concept of the bus valve terminal. Integrating multiple valve controls into a single network can simplify processes extensively. Using a bus valve terminal allows for seamless data transmission and improved interface functionality across devices. Benefits include not only cost savings but also enhanced operational efficiency in environments requiring high precision. Such systems support dynamic adjustment of production lines, aligning operational capabilities with evolving market demands.

In summary, the evolution of valve terminals marks a pivotal shift in industrial automation. By addressing common failures with innovative solutions, operators can reap significant benefits in performance and efficiency. As industries evolve and adapt, manufacturers like DECOWELL offer reliable and advanced technological options, ensuring a competitive edge for businesses striving for excellence.